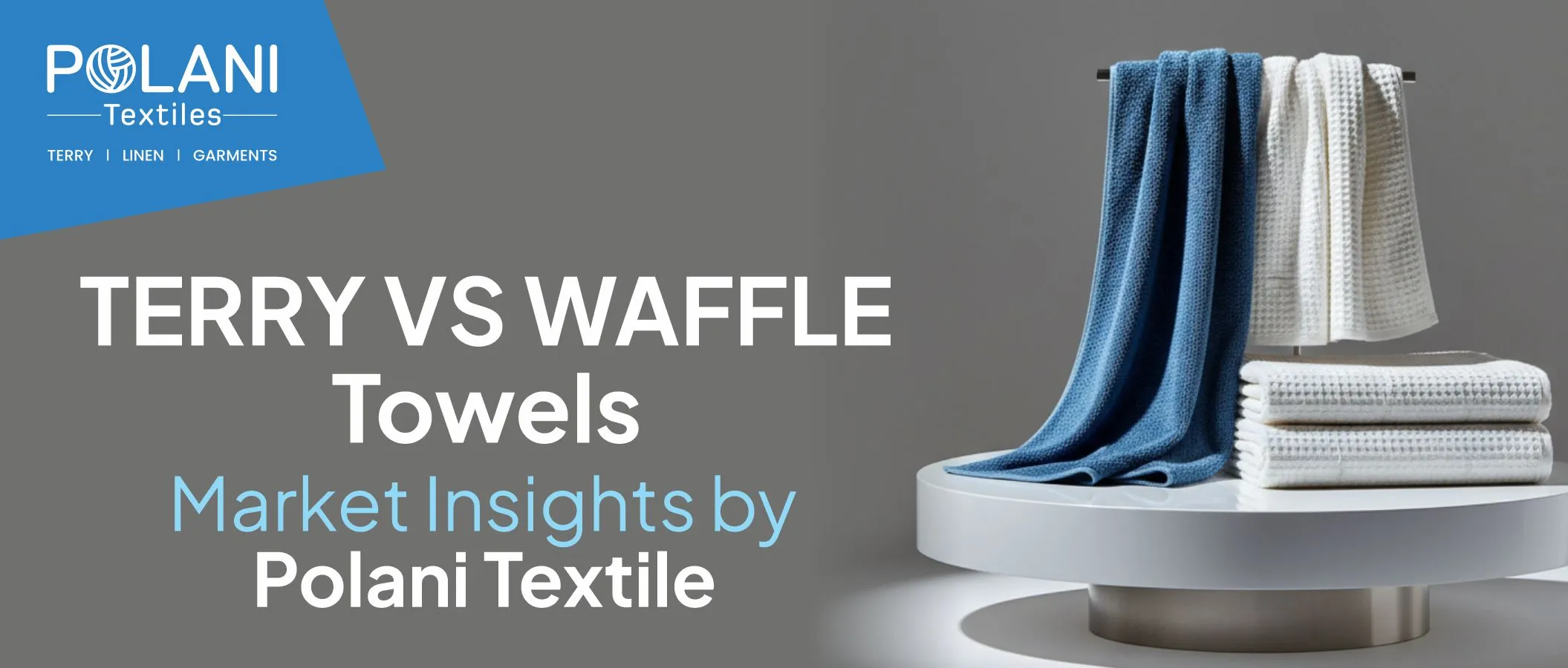

Terry towels and waffle towels serve different market needs. Terry towels are plush, thick, and highly absorbent, ideal for hotels, spas, and luxury retail. Waffle towels, on the other hand, are lightweight, fast-drying, and compact, perfect for gyms, travel, and modern minimalist markets. Choosing between them depends on your target audience, climate, and end-use preferences.

Understanding the Difference Between Terry and Waffle Towels

The main difference between terry and waffle towels lies in their fabric structure. Terry towels feature looped cotton yarns on both sides, creating a soft and fluffy texture that enhances absorbency and comfort. In contrast, waffle towels have a grid-like, textured pattern that resembles a honeycomb. This design makes them thinner, smoother, and quicker to dry. Both are made from cotton, but their weaving style determines their weight, feel, and performance. At Polani Textiles, both types are manufactured using premium-grade cotton, ensuring that softness and durability remain consistent across all collections.

Absorbency and Drying Time

Terry towels are known for their exceptional absorbency due to their thick pile of loops that trap and hold water efficiently. This makes them the go-to choice for hotels, spas, and homes where comfort and high absorbency are key. However, because of their density, terry towels take longer to dry. Waffle towels, in comparison, absorb water quickly but release it faster during drying. Their lightweight structure allows for better airflow, making them suitable for humid climates or travel use where quick drying is essential. For global importers, this difference can determine the ideal product mix depending on the customer’s climate and usage habits.

Terry towels are known for their exceptional absorbency due to their thick pile of loops that trap and hold water efficiently. This makes them the go-to choice for hotels, spas, and homes where comfort and high absorbency are key. However, because of their density, terry towels take longer to dry. Waffle towels, in comparison, absorb water quickly but release it faster during drying. Their lightweight structure allows for better airflow, making them suitable for humid climates or travel use where quick drying is essential. For global importers, this difference can determine the ideal product mix depending on the customer’s climate and usage habits.

Texture and Feel

The feel of a towel is one of the biggest buying factors for consumers. Terry towels offer a plush, cozy texture that feels luxurious against the skin, ideal for premium markets and hospitality clients who value comfort. Waffle towels, on the other hand, have a smoother and more tactile feel that becomes softer with every wash. Their lightweight design gives a refined and minimalist look that appeals to modern home and lifestyle markets. Polani Textiles’s weaving technology ensures both styles maintain their quality and texture, even after repeated use and industrial laundering.

Durability and Maintenance

Durability depends on both weave strength and yarn quality. Terry towels are naturally thicker, providing higher resilience to frequent washing and daily use. They retain their softness and thickness over time, making them suitable for high-turnover environments like hotels and spas. Waffle towels, though thinner, are surprisingly strong due to their tight weave. They resist shrinking and fraying and take less energy to launder because of their low drying time. Polani Textiles tests both towel types for colorfastness, tensile strength, and shrinkage to ensure they meet international hospitality and export standards.

Choosing the Right Towel for Your Market

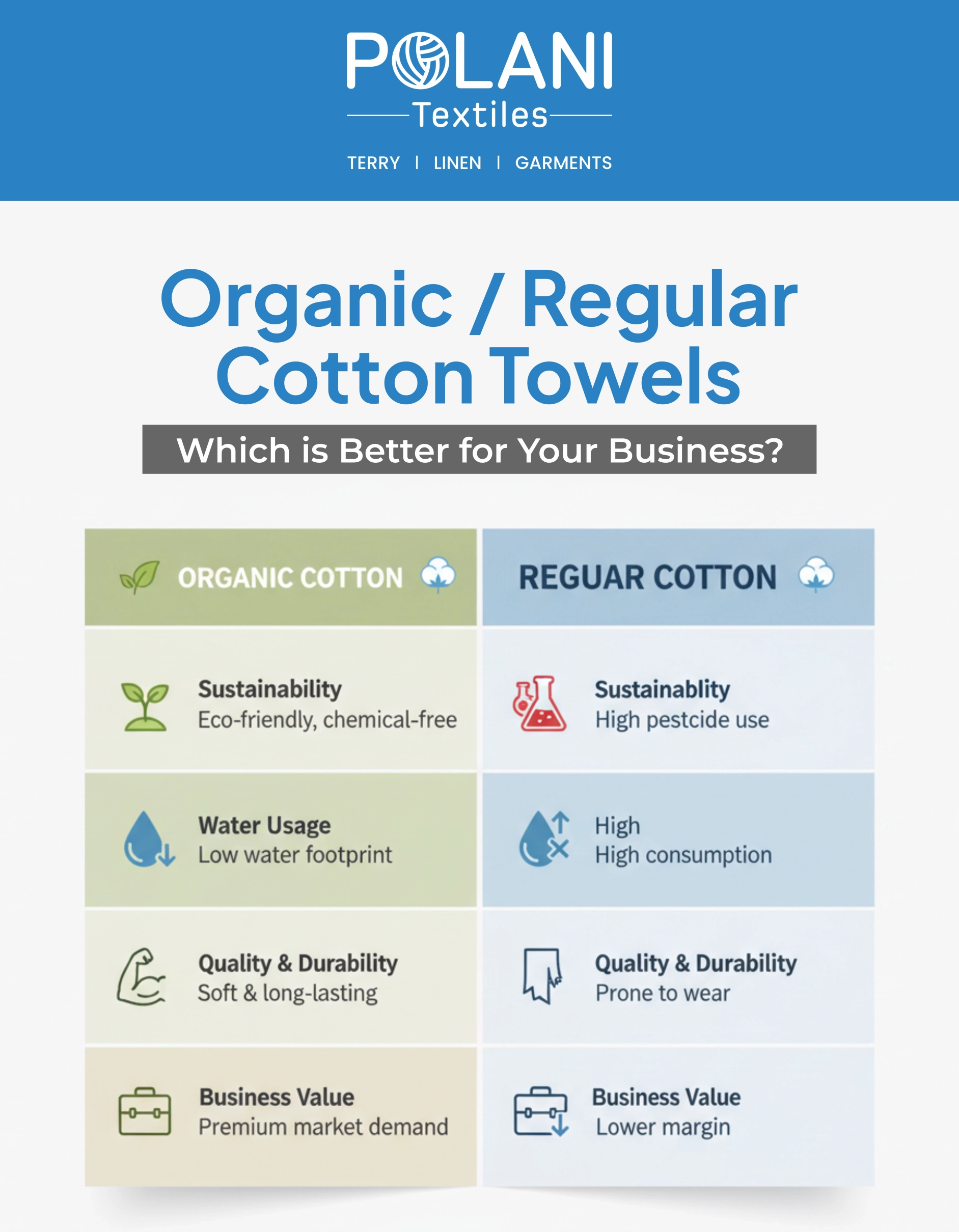

When selecting between terry and waffle towels, consider your market’s lifestyle, climate, and end-user expectations. For cooler regions or luxury hospitality sectors, terry towels are often preferred for their thickness and comfort. In contrast, for warmer regions, gyms, or eco-conscious markets, waffle towels offer practicality, elegance, and energy efficiency. Many retailers combine both in their product range to cater to diverse customer needs. Polani Textiles helps importers analyze their market trends to select the right towel type, GSM, and finish to maximize appeal and profitability.

How Polani Textiles Ensures Quality in Every Weave

At Polani Textiles, quality starts from yarn selection. Our terry towels use long-staple combed cotton for maximum softness and water absorption, while our waffle towels are woven with precision looms that create perfect honeycomb patterns. Each batch undergoes GSM testing, finishing treatments, and durability checks to ensure consistency. With over decades of experience in textile manufacturing and export, Polani Textiles supports global clients with custom production, labeling, and packaging, meeting the unique requirements of each market segment.

Frequently Asked Questions (FAQ)

Conclusion

Both terry and waffle towels have their unique strengths, and the right choice depends on your market’s needs. Terry towels offer plush luxury and superior absorbency, while waffle towels provide practicality, lightness, and a modern aesthetic. Understanding your audience helps determine which product will drive better sales and satisfaction. With advanced manufacturing capabilities and a deep understanding of global market demands, Polani Textiles delivers both styles with unmatched quality, performance, and consistency, helping importers meet every segment’s expectations effortlessly.