For B2B buyers, choosing between Turkish cotton and regular cotton is no longer a cosmetic or marketing decision. It directly influences product lifespan, procurement risk, compliance performance, and long-term cost efficiency. While Turkish cotton is often perceived as a premium option, the real value lies in how it performs in bulk sourcing, repeated laundering, and international trade environments. Understanding Turkish Cotton vs Regular Cotton at a technical and commercial level helps buyers make smarter sourcing decisions that support both operational efficiency and brand positioning.

Fiber Quality Alone Is Not Enough Yarn Construction Matters

When comparing Turkish Cotton vs Regular Cotton, many buyers focus only on fiber origin. However, yarn construction plays a critical role in real-world performance. Turkish cotton is commonly processed into ring-spun yarns, which are tighter, smoother, and more durable. This structure improves absorbency, reduces linting, and maintains fabric strength after repeated washes.

Regular cotton, especially in cost-focused production, is often spun using open-end yarns. While this reduces upfront cost, it can lead to faster pilling, weaker tensile strength, and inconsistent texture over time. In hospitality, retail, and institutional use, these differences translate into higher replacement rates and quality complaints.

Why Yarn Specification Is Critical for B2B Procurement

One common mistake buyers make in the Turkish Cotton vs Regular Cotton comparison is assuming fiber origin alone guarantees quality. If Turkish cotton is used with open-end yarn construction, much of its performance advantage is lost.

For procurement clarity, specifications should clearly state:

100% Turkish cotton, ring-spun yarn

This ensures better durability, consistent hand-feel, and stronger wash performance, all essential for long-term supply contracts and customer satisfaction.

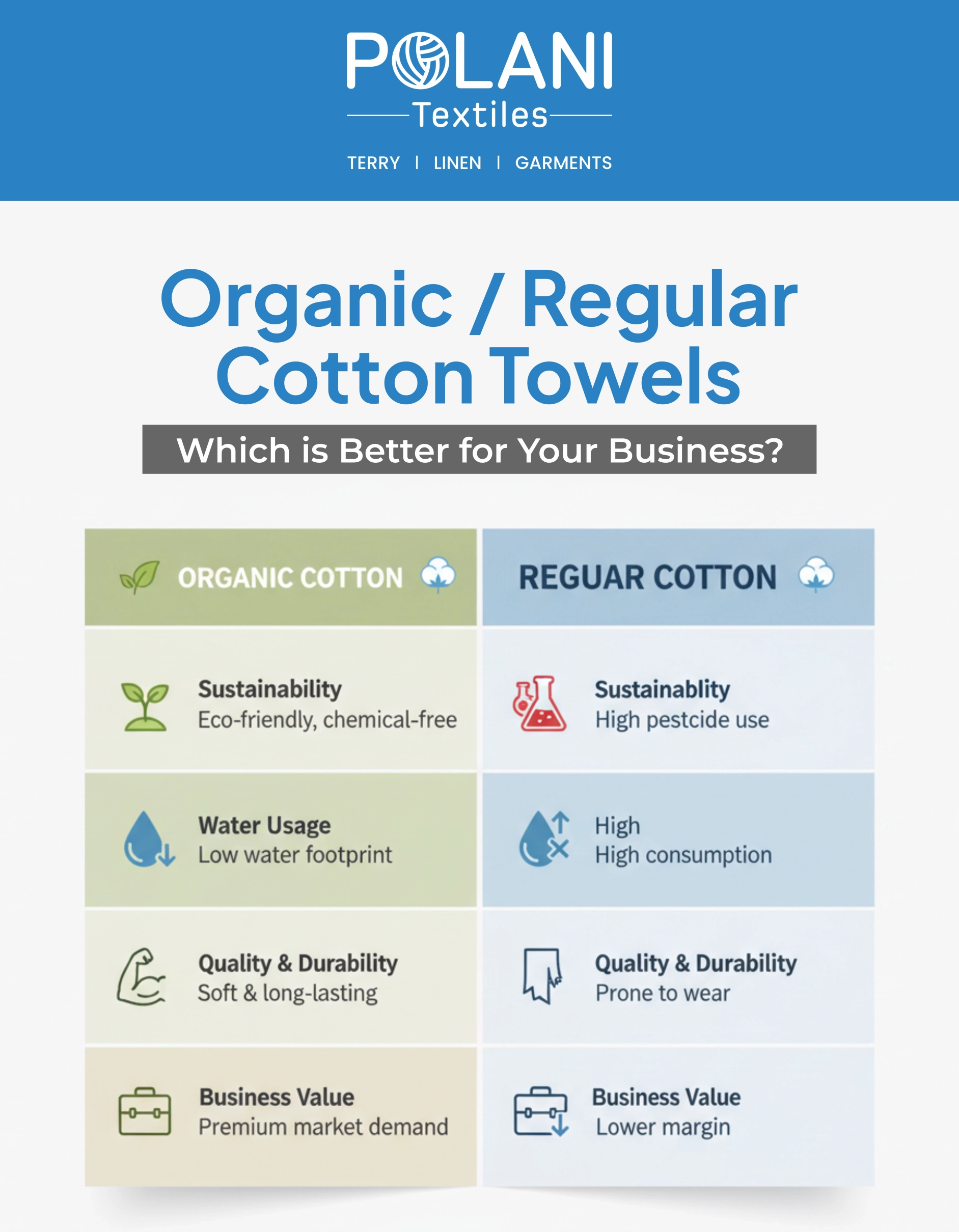

| Feature | Turkish Cotton Towels | Regular Cotton Towels |

|---|---|---|

| Material | Long-staple Turkish cotton | Often short-staple cotton or blended fibers |

| Feel | Lightweight, smooth, gets softer over time | Thicker and heavier, may stiffen after repeated washing |

| Absorbency | Highly absorbent with quick-dry performance | Absorbent but slower drying |

| Durability | Stronger fibers, better wash resistance | Higher wear and tear over time |

| Common Use | Travel, spa, hotels, beach, premium bathrooms | Mostly standard bathroom use |

| Style & Appearance | Chic, flat-woven, modern and versatile | Fluffy, basic, traditional look |

| Eco Impact | Requires less water and energy to wash and dry | Heavier washing, longer drying cycles |

Compliance, Testing, and Performance Reliability

Modern B2B sourcing requires more than basic certifications. When evaluating Turkish Cotton vs Regular Cotton, buyers should request technical test reports alongside OEKO-TEX or GOTS certifications. These reports provide measurable proof of performance.

Key tests include pilling resistance, tensile strength, colorfastness, and GSM consistency. Products made from Turkish cotton generally perform better in these tests due to longer staple fibers and stronger yarn integrity. This reliability reduces compliance risk, particularly in hospitality and export contracts where performance failure can result in penalties.

MOQ Flexibility and Its Commercial Impact

Minimum order quantities are an often-overlooked factor in cotton sourcing decisions. Regular cotton suppliers frequently rely on high MOQs to maintain margins, limiting flexibility for buyers testing new collections or managing seasonal demand.

In contrast, Turkish cotton suppliers often operate within vertically integrated production systems. This allows buyers to negotiate more flexible MOQs, split orders across multiple product categories, and customize specifications without excessive volume commitments. From a procurement standpoint, this reduces inventory exposure and improves cash-flow management.

Trade, Duties, and Customs Efficiency

From a global trade perspective, Turkish Cotton vs Regular Cotton also affects customs handling and landed costs. Turkish textile products often benefit from structured trade agreements, particularly within Europe, leading to smoother documentation, faster clearance, and lower inspection frequency.

Regular cotton imports from certain regions may face longer port dwell times, higher inspection rates, and increased scrutiny during trade reviews. Over time, these delays can disrupt supply chains and increase operational costs for importers.

Consistency Across Production Batches

One hidden cost associated with regular cotton is batch inconsistency. Because regular cotton is often blended from multiple sources to meet pricing targets, buyers may experience variation in color, GSM, and fabric feel between shipments.

Turkish cotton is sourced from a more geographically concentrated region, offering stronger batch-to-batch consistency. This is particularly important for hotel chains, franchise retailers, and private-label brands that rely on uniform product standards across multiple locations.

End-User Perception & Repeat Business

Beyond technical performance, Turkish Cotton vs Regular Cotton also influences customer perception. End users consistently associate Turkish cotton with premium quality, comfort, and spa-grade standards. In contrast, products labeled simply as “100% cotton” are often viewed as generic.

This perception impacts guest satisfaction in hospitality, product reviews in retail, and reorder frequency in wholesale programs. While regular cotton may meet functional requirements, Turkish cotton actively supports brand differentiation and long-term customer loyalty.

When Regular Cotton Is Still the Right Choice

Despite its advantages, Turkish cotton is not always the most practical option. Regular cotton remains suitable for price-sensitive products, promotional items, short replacement cycles, and back-of-house applications where durability and perception are less critical.

Many experienced B2B buyers adopt a segmented sourcing strategy, using Turkish cotton for customer-facing products and regular cotton for operational or low-touch use. This approach balances cost control with value optimization.

Final Insight for B2B Buyers

The comparison of Turkish Cotton vs Regular Cotton is not about luxury versus budget — it is about managing total cost of ownership, supply chain risk, and brand consistency. While regular cotton may offer lower upfront pricing, Turkish cotton delivers long-term advantages in durability, compliance reliability, trade efficiency, and customer perception.

For B2B buyers focused on sustainable sourcing, operational stability, and scalable growth, Turkish cotton represents a strategic investment rather than an added expense.